Products.

OSSIS products have evolved from years of collaboration between surgeons and engineers.

This combined expertise delivers a rapid, efficient and long-lasting solution.

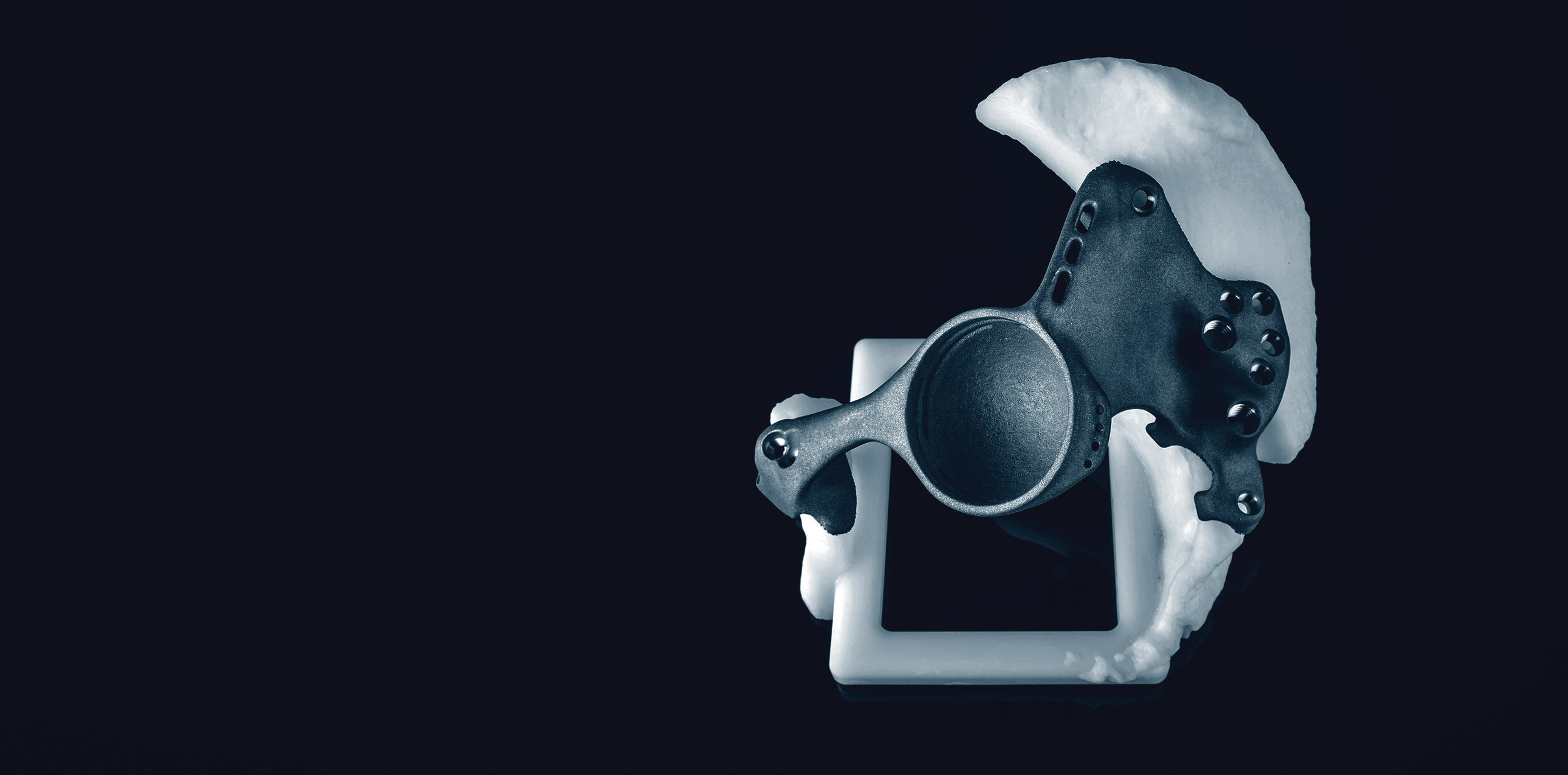

Acetabular solution

OSSIS provides custom acetabular implants for severe bone loss and pelvic dissociations—which are known to be time-consuming, challenging surgeries without a customised solution.

These custom implants provide a robust and reliable solution for both revision surgeries and primary surgical solutions including, but not restricted to:

Dysplasia

Osteolysis

Bone loss

Fractures

Infection

Trauma.

AceOs

AceOs Plus

Oncology solutions

For complex oncology and tumour cases in the pelvis, OSSIS creates a custom implant to replace the missing bone and recreate stable function:

Using 3D printing technology and engineering expertise, we can recreate anchor points for reattaching soft tissue

Creating custom cutting guides, OSSIS supports surgeons to plan bone removal pre-operatively

With our advanced design and manufacturing process, a delivery time of three to four weeks after receiving the patient’s scan data.

In urgent oncology cases, the speed and durability of our custom implants has enabled life-changing results for patients.

Oncology Custom Implant

Hemi Pelvis Implant

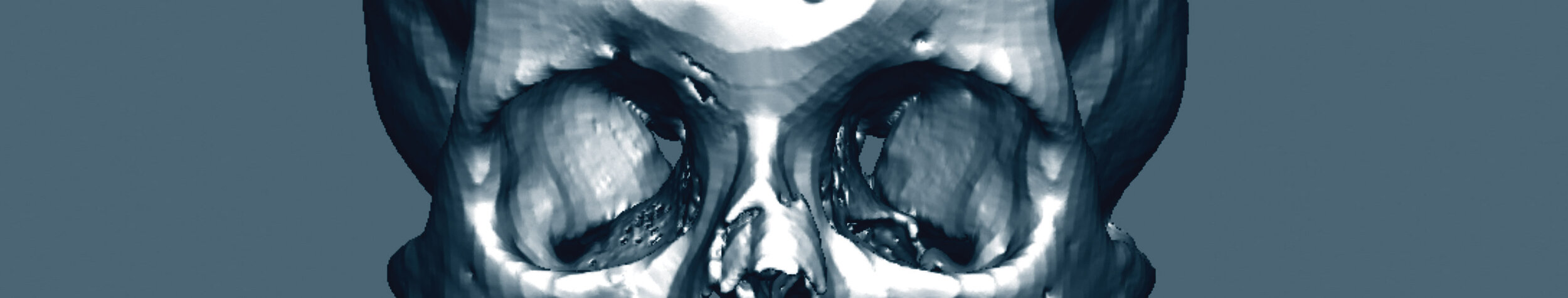

Surgical support

Our 3D printed anatomical models and osteotomy guides allow surgeons to visualise alternative treatment options, as well as providing a useful aid to explain these treatment options to patients and theatre colleagues.

Sterilisable anatomical models are provided for intraoperative use with every OSSIS implant.

“For tumour cases, there is literally no alternative other than these 3D printed implants. Tumours grow quickly, and surgeons need a solution that can be delivered fast. OSSIS can deliver an oncology implant in 3 weeks.”

OSSIS provides implant solutions for complex cases.

Where surgeons have previously been restricted to using standard off-the-shelf implants to create a complex solution during surgery, the OSSIS design and manufacturing process allows surgeons to accurately plan and avoid unknown obstacles prior to the procedure.

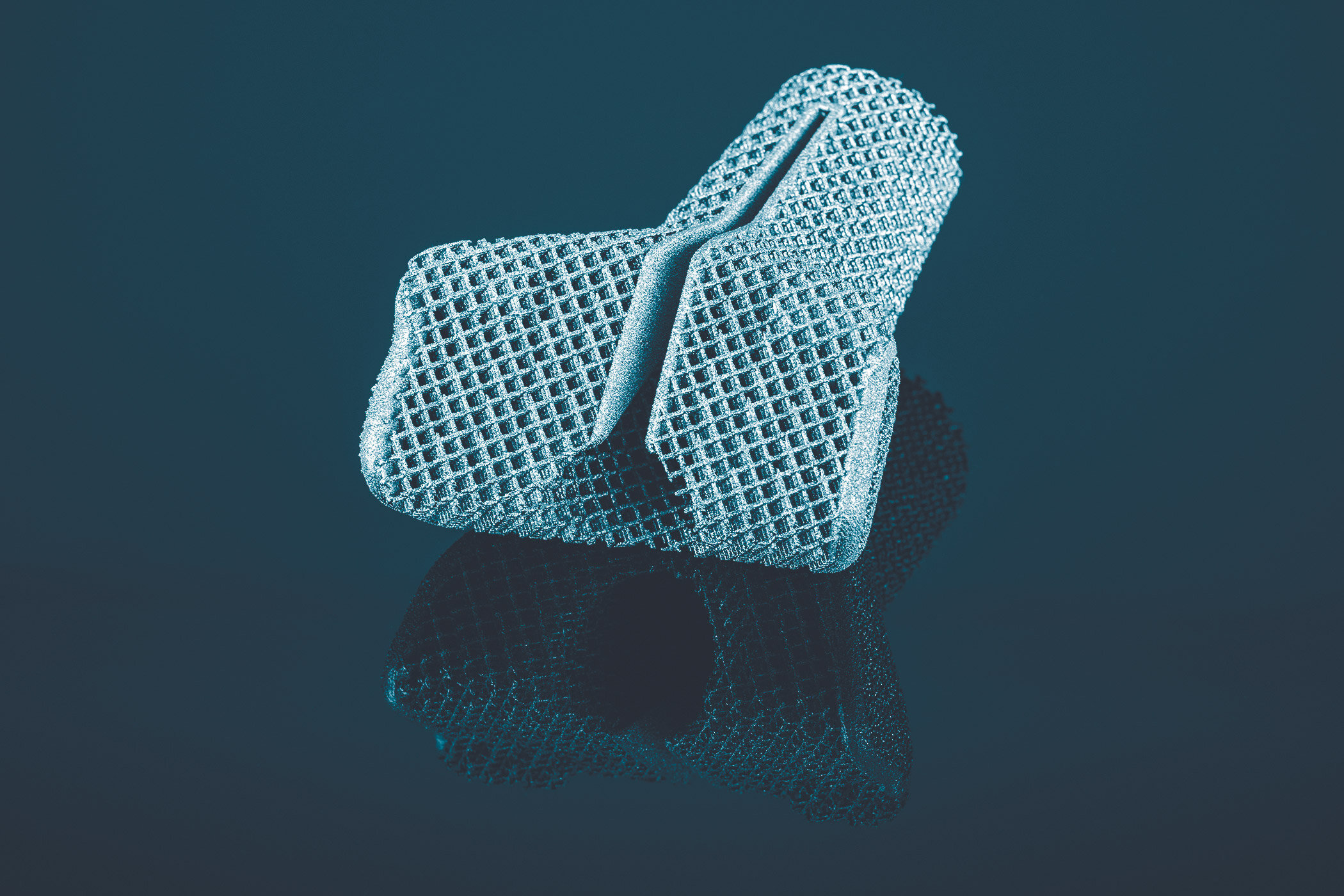

With our ‘one implant per life’ philosophy, OSSIS 3D prints a unique trabecular structure onto our implants as a scaffold for osseointegration.

We can provide plastic anatomical models and trials of the implant to support preoperative surgical planning, and provide a useful reference for discussion with colleagues and education of patients around their treatment options.

With advanced 3D printing technology and a collaborative approach throughout the design phase, the final solution is completely customised to the patient’s needs.

OSSIS products are not yet available for use in the USA.